The Environmental Advantages of Concrete Cast-In-Place Constructions The Productivity Of Your Projects

In the realm of civil construction, few areas consume as many natural resources, generate as much waste, and emit as much CO2 as the building sector. It is crucial to address the global demand for environmentally-friendly buildings, which requires the collaboration of various stakeholders in the industry. At FORSA, we understand the urgency to minimize our environmental impact and provide sustainable solutions. In this blog, we explore the environmental benefits of our concrete Cast-In-Place construction system, as supported by studies and industry experts.

Reducing Waste and its Environmental Impact

Traditional construction methods result in significant waste generation on construction sites. However, the implementation of our concrete cast-in-place system has shown a remarkable reduction in waste. Leading companies such as MRV and Rottas Constructora have reported waste reductions of up to 50% by adopting our system. Additionally, HM Engenharia e Construções witnessed a substantial decrease in debris generation compared to structural masonry. These findings confirm that our concrete cast-in-place system minimizes waste and contributes to a cleaner and more sustainable construction process.

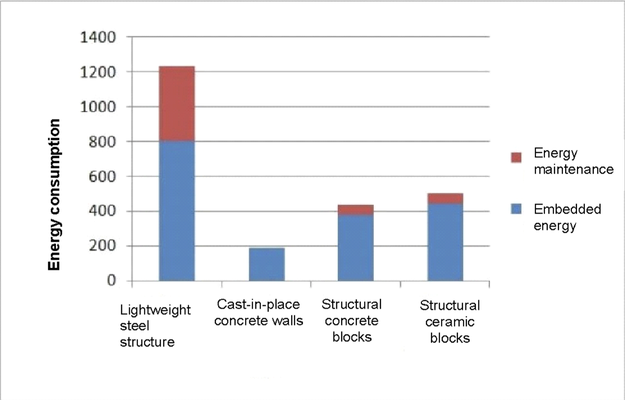

As seen in the table above, the concrete cast-in-place system showed the best results for this indicator, with 63 lbsCO2/ft².

Durability and Low Maintenance

Longevity plays a significant role in sustainable construction practices. Our concrete cast-in-place system excels in this aspect, as it is designed for a useful life of at least 30 years, with the potential to extend it to 50 years or more under satisfactory conditions. By utilizing durable materials and implementing proper maintenance procedures, our system minimizes the need for costly replacements and reduces the consumption of non-renewable resources. This durability aspect contributes to the overall sustainability of our construction projects.

Cost-effectiveness through Productivity

Economic prosperity is one of the pillars of sustainability, and our concrete cast-in-place system offers cost-effective benefits through enhanced productivity. By optimizing the use of natural resources, minimizing waste, and reducing greenhouse gas emissions, our system provides a more efficient construction process. Furthermore, our collaboration with subsystem suppliers allows us to merge advanced technology and productivity while maintaining a lower environmental footprint. The resulting increase in productivity benefits both our clients and the environment.

Conclusion

The concrete cast-in-place system offered by FORSA provides a comprehensive solution for sustainable construction. Endorsed by industry standards and embraced by a broad and organized production chain, our system prioritizes environmental responsibility without compromising technical excellence. With reduced waste generation, energy efficiency, durability, and enhanced productivity, our concrete wall system paves the way for a promising and sustainable future in the construction industry.

At FORSA, we are committed to providing personalized technical support and sustainable solutions throughout all stages of your construction projects. We hope this blog has shed light on the environmental advantages of our concrete cast-in-place construction system. Contact us today to learn more about our services and join us in building a greener future.